油壓產品

探索昌佳優質液壓元件

作為液壓元件製造商,昌佳致力於為客戶提供高效的液壓技術解決方案和產品。液壓擺線馬達驅動旋轉機構,液壓閥控製油路的方向和壓力,液壓泵提供動力油源。所有這些元件在農業機械、工程機械和自動化設備中協同工作,確保液壓系統的高效運作。

客製化服務

為不同行業提供客製化液壓元件服務

作為客製化液壓元件製造商,我們專注於液壓馬達、液壓閥和液壓泵的研發與製造。從標準產品到複雜系統,我們竭誠為工業、工程機械、農業等領域的客戶提供一對一液壓客製化服務。無論您面臨特殊工況、嚴苛環境,或是追求更高的能源效率,我們的工程師團隊都將結合多年的產業經驗,為您打造專屬的客製化服務。

1

油壓馬達

這些馬達採用精密設計,具有可自訂的油口尺寸、法蘭配置和油漆飾面,提供客製化的扭力和速度規格、適應性安裝選項、壓力額定值客製化和流量優化,以滿足不同的工業要求。

2

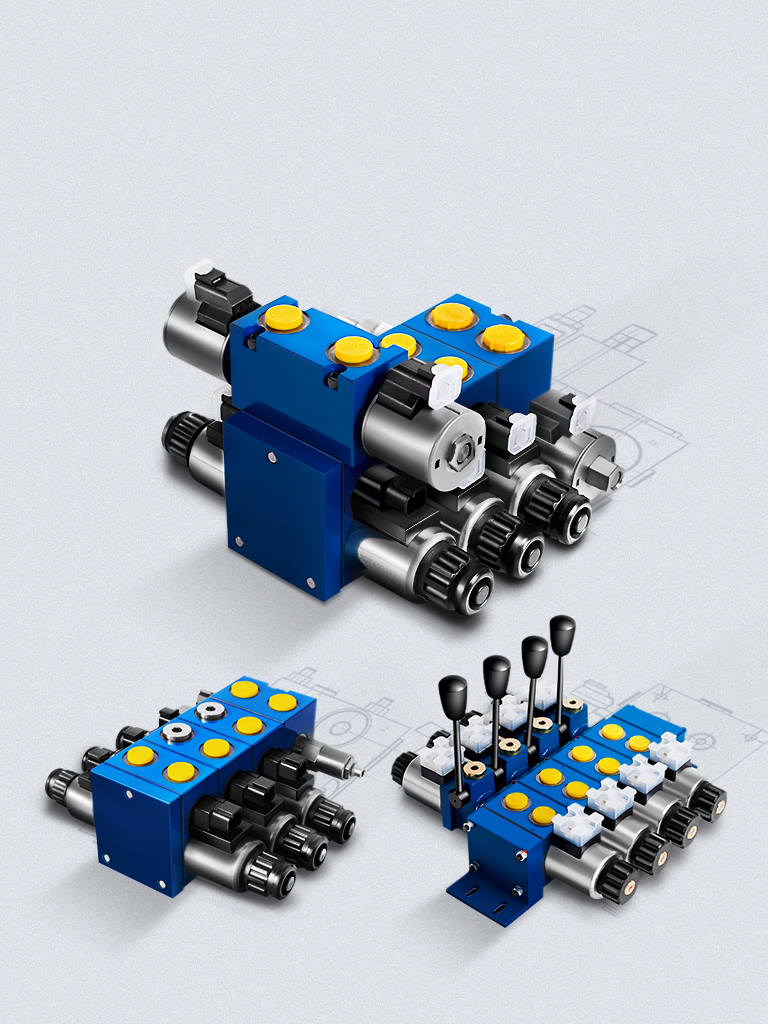

液壓閥

我們精密設計的閥門提供全面的客製化解決方案,以滿足精確的操作要求。從針對特定安裝需求量身訂製的連接埠配置(螺紋、法蘭或歧管安裝),到針對耐腐蝕或高溫環境優化的閥體材料(不銹鋼、鑄鐵或輕質合金),各方面均可客製化。

3

液壓泵浦

可自訂的服務包括流量/壓力調整、材料選擇(例如耐腐蝕合金)、安裝介面修改、性能最佳化(變速控制、降噪)以及針對極端溫度、黏度或潛水環境的專門設計。

沒有數據

應用場景

作為專業的客製化液壓元件製造商,昌佳深耕液壓核心技術,以高性能元件、智慧系統、價值鏈服務,為全球客戶提供超越期望的解決方案。

農業機械

工程機械

市政環衛車輛

應用場景

昌佳深耕液壓核心技術,以高效能零件、智慧系統和價值鏈服務,為全球客戶提供超越期望的解決方案。

農業機械

工程機械

市政環衛車輛

資訊中心

精選部落格與新聞

The pressure valves are highly valuable in ensuring the hydraulic and pneumatic systems are safe and effective. They regulate the pressure and guard the machines against excessive pressure or unexpected spikes. Without testing or adjusting these valves, the system may be rundown of pressure. It may also overheat, operate unevenly, or may even break up.

2026

02

09

Selecting the appropriate hydraulic valve is extremely critical to your hydraulic system. The valve determines the flow and pressure of the fluid and direction, which influence the level of functioning of your machine. The incorrect choice of the valve may lead to a delay in response, a decrease in pressure, overheating, or frequent failures. That is why it is also important to know what to seek before purchasing. The reason is to understand how your system operates.

2026

02

08

In a hydraulic system, the pressure and direction of flow of fluid are controlled by hydraulic valves. It might be the construction machines or the factory equipment. These valves determine the flow of fluids and the provision of power. When one of the valves begins to fail, the entire system may begin to slow down, react slowly, or even cease all operations.

2026

02

06

沒有數據

聯絡我們

您有疑問嗎?

我們的貿易客戶經理團隊將為您提供從報價到交付等所有專案環節的無縫協助。我們的貿易專家隨時為您提供協助。

重慶市江北區兩路寸灘保稅港區水港功能區S10-6-5

昌佳是全球液壓技術的領導者,集研發、製造、銷售和服務於一體,推動核心液壓元件的創新和生產。

![]() 公用信箱:info@changjia.com

公用信箱:info@changjia.com

聯絡我們

蒂娜電話:+86 135 0836 3447 WhatsApp: +86 135 0836 3447電子郵件:tina@changjia.com

安妮電話:+86 158 2639 0716 WhatsApp: +86 158 2639 0716電子郵件:anne@changjia.com

沒有數據

版權所有 © 2025 昌嘉公司